Building: Amp Board Power Up and Test

Now let's hook your amp board modules (which are already mounted on their heat sinks) to the power supply (already tested) and see if this all works together!

I recommend powering up and testing the amp boards, one at a time, BEFORE assembling the whole chassis. Once we're satisfied that the amp boards power up correctly, then we will assemble the whole chassis. The upside of this approach is that if there is something wrong with an amp board, it will be a lot easier to disassemble and troubleshoot if the whole chassis isn't all buttoned up. The downside is that it's a lot easier to accidentally break or short something while things are loose and not all screwed together. So, once again, go slow and be careful.

DON'T RUSH. This is the part where it gets exciting, so it's tempting to rush. That's how catastrophic mistakes get made. Take your time, double check connections, don't do it if you're in a rush to get somewhere. ELECTRICITY IS DANGEROUS, so stop and think and don't take chances. Specifically:

- Use insulated, non-conducting tools for adjusting the bias and offset.

- Don't connect the power cord until you've double checked your connections and are ready to test.

- Use a dim bulb tester for the first power up.

Step #1: Amp board power connections

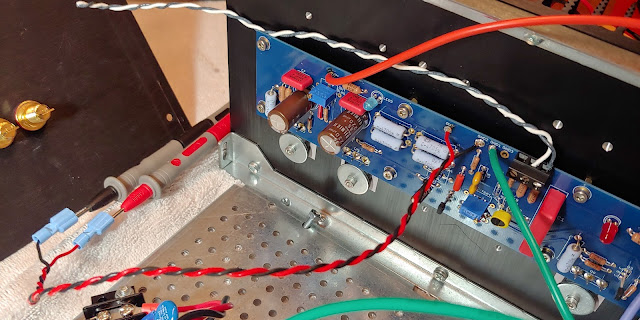

Starting where we left off with the same layout of the chassis components from the power supply testing, affix one heat sink/amp board module to the front panel, using the short silver machine screws included with the back panel kit. These screws connect the heat sink rails to the front panel. I used one screw to connect the heat sink to the front panel, but using two is probably better. This stands up the front panel and forms a stable "L" with the heat sink that won't fall over as we're powering up and testing (see photo above).

If you disconnected the power supply components after previously testing it, make sure you test it again after re-assembly, before making any amp board connections, just to make sure it's still working as it should.

Next, you will connect the rectified, filtered DC power from the power supply board (the Euroblock connectors on top) to the power wires that we've already installed on the amp boards (V+, GND, and V-). Some things to keep in mind before you start:

- The Euroblock connections are a tight fit for 16 gauge stranded wire, so make sure you twist the exposed stripped wire tightly and leave no stray strands protruding from the connector that might touch a neighboring wire.

- DO NOT TIN the wire ends that are going into the Euroblock connectors (after cooling, solder will continue to slowly flow, resulting in gradual loosening of screw-tight connectors). Just strip ends and twist.

- Make sure to connect the correct wires to the correct connector positions on the power supply board (V+ to V+, V- to V-, and GND to GND). You'll see that I drew a "+" and "-" on the back panel itself to remind myself which is on which side of the power supply board.

- The power supply board offers one Euroblock for V+ connections, two Euroblock connectors for GND connections, and one Euroblock for V- connections. Once you've found the correct Euroblock connector, you can use any of the available ports for the connection.

If you're following the guide so far, you shouldn't input signal wires connected to your amp board Euroblock connector yet. You'll see in the photo above that I'd already connected mine, but you don't need them for initial testing.

Now is a good time to terminate the twisted pair output speaker connection wires (red/black in mine) with the same Panduit 0.250 female disconnect connectors that we used for the power supply connections. We will be using these as test points, so having them fully insulated inside a connector is a good way to prevent accidental shorting as we test.

Step #2: First power up

Before powering up:

- Hook up your AC from your wall socket through the dim bulb tester. This will let you know whether you've got a dead short somewhere, hopefully with enough time to shut it down before something gets damaged or catches fire.

- Make sure that no uninsulated parts of the input wires or speaker connection wires are touching (as mentioned above, you don't need any input wires connected yet, and your speaker connection wires should now be terminated in insulated connectors).

- Double check the amp-board-to-power-supply-board connections, making sure that you've got the correct wires going to the correct Euroblock connectors, and that the connections are securely screwed down.

Assuming this all went according to plan and the dim bulb tester behaved as expected, power off the amp and unplug. REMEMBER THAT THE POWER SUPPLY CAPS STAY CHARGED EVEN AFTER YOU TURN OFF THE POWER, SO USE CAUTION.

Step #3: Second power up and adjusting bias and offset

REMOVE THE DIM BULB TESTER (the amp will not bias up fully while the dim bulb tester is in the circuit, as the bulb will be absorbing some of the current) and connect the power cord directly to the back panel AC inlet module. Do not turn on the amp yet.

We will be using the R27 potentiometer to adjust bias (this pot actually sets the AC gain of the Aleph Constant Current Source, but indirectly adjusts bias, so we'll call it bias for convenience). DC offset is controlled by the other potentiometer on the amp board, R7. These two aspects of the amp are indirectly related, so we will have to adjust each of them repeatedly, until we find an optimal balance.

For this initial test, it'll be enough to get bias and offset roughly in the ballpark, to make sure the amp board is operating as intended. Assuming things are working correctly, final adjustments will be made after the entire chassis is assembled (the settings are influenced by temperature, so there's no point in trying to get them exactly on target until the chassis is assembled, since that will impact the thermal environment for the boards).

Switch on the back panel power switch. Using your multimeter, measure the voltage drop across one of the source resistors on the right side of the amp board. Be very careful not to accidentally short something when taking this measurement. This is where my hook clip leads were invaluable (you could also try leads with small, insulated alligator clips).

Using an insulated or non-conductive screwdriver or trimmer tool (you don't want to drop a metal tool and risk shorting something), adjust R27 so you read approximately 0.35V (350mV) across this resistor.

Leaving the power on, let the amp board sit and warm up for 1/2 hour.

Once warm, re-adjust R27 so you read 0.4V (400mV) across the resistor.

Now measure the DC offset across your speaker connections. If you only have one multimeter, you will need to disconnect probes from the source resistor (if you have two multimeters, lucky you, it'll go faster if you can see both bias and offset at once!). You'll see that I simply inserted the multimeter probes into the connectors on the speaker output wires.

Now adjust R7 until you see zero voltage (anything less than 10 millivolts is fine at this point, later we will get it lower). Why is this important? Musical content is AC -- your speakers are not meant to see significant DC voltages. A DC voltage across the speaker terminals does not generate sound, but it does displace the voice coil of your speaker, generating heat and potentially distortion. So you want the DC offset at the speaker terminals to be as near zero as possible.

Now, back to the source resistor and R27. Check to see that the bias didn't change much with the change in offset, and re-adjust R27 if necessary.

You don't need to get the offset and bias perfect now. That comes later, once the amp is all assembled. So long as the measurements close and are responsive to adjustments in R27 and R7, consider the test passed! Congratulations. (If thing are not working as they should, now is the time to power down, take well-lit photos, and head over to the DIYAudio "Aleph J illustrated build guide" thread to ask politely for help.)

Once you are satisfied that your first amp board/heat sink module is working correctly, power down the amp and wait overnight for the power supply capacitors to drain. (You can always check whether the power filter supply caps are discharged by measuring the voltage between V+ and GND and V- and GND. They should discharge faster with the amp board load attached than they did when you tested the power supply with no load attached.)

Step #4: Repeat steps #1-3 for the other channel

Connecting and testing the second amp board/heat sink module works the same way as the first one. Make sure you connect the power wires to the power supply board correctly, paying attention to V+, GND, and V-. Use the dim bulb tester for the first power up.

Here's a photo of mine with both channels hooked up for testing. You'll see that I've not taken much care with wire lengths or routing. There's time for all that once you're satisfied that you can adjust bias and offset correctly in both channels.

Comments

Post a Comment